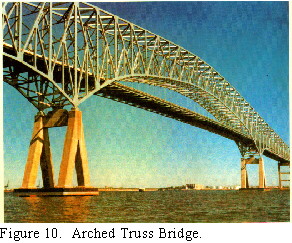

For In Straws We Trussed, we will assume the role of a structural engineer and explore some of the basic concepts that are important in the design of structures. We will examine a particular structural form, known as a truss. Trusses are made of long, thin pieces, usually of steel or wood, connected together in a series of triangles. Bridges, towers and roof supports are common places to find trusses.

(from web.umr.edu/~dougc/bridge/Web_Instructions.htm)

Let's begin with two important concepts in the design of truss structures: compression and tension.

Compression - the process or result of something being pressed or squeezed.

Tension - the process or result of something by being stretched or pulled.

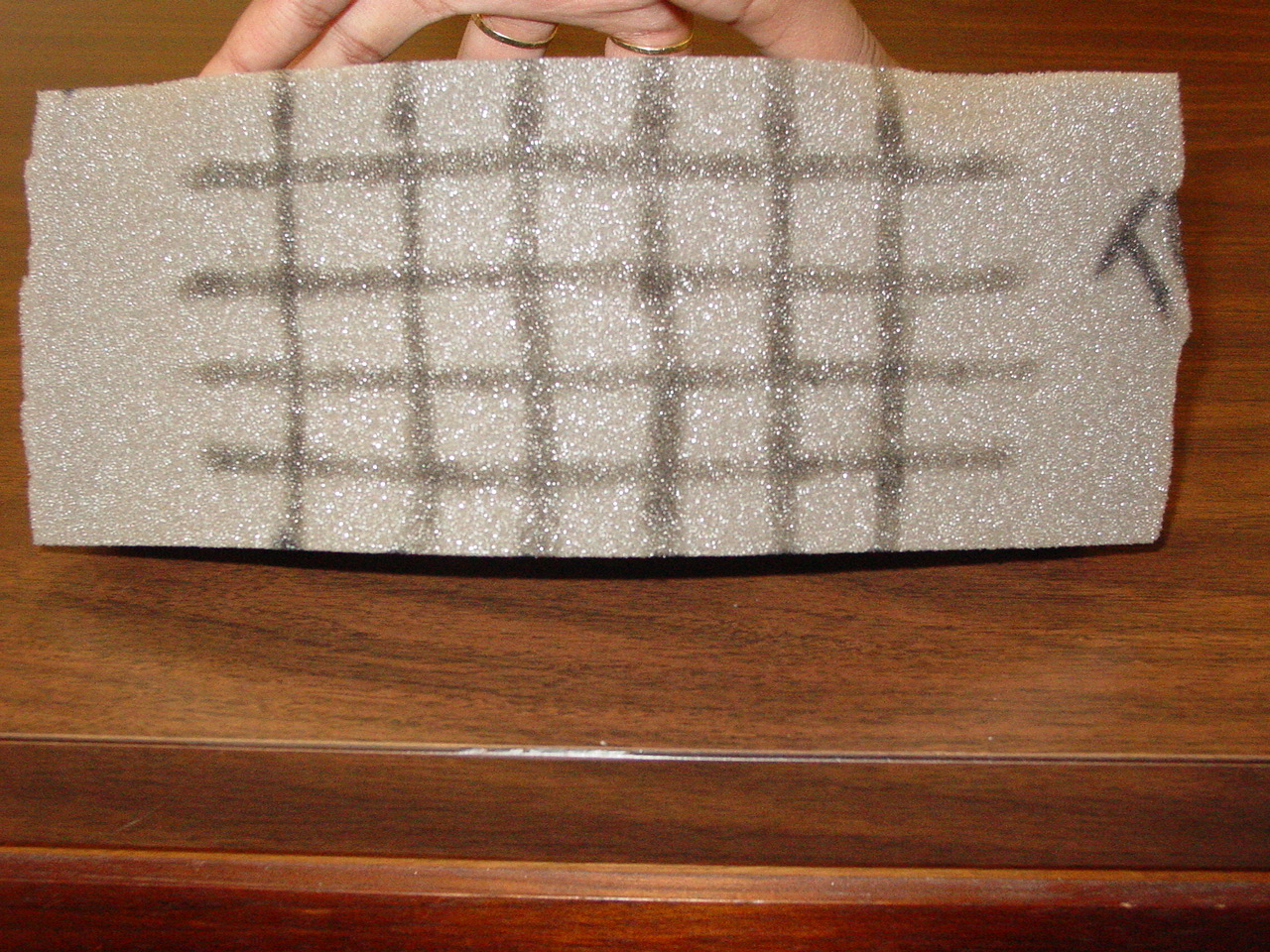

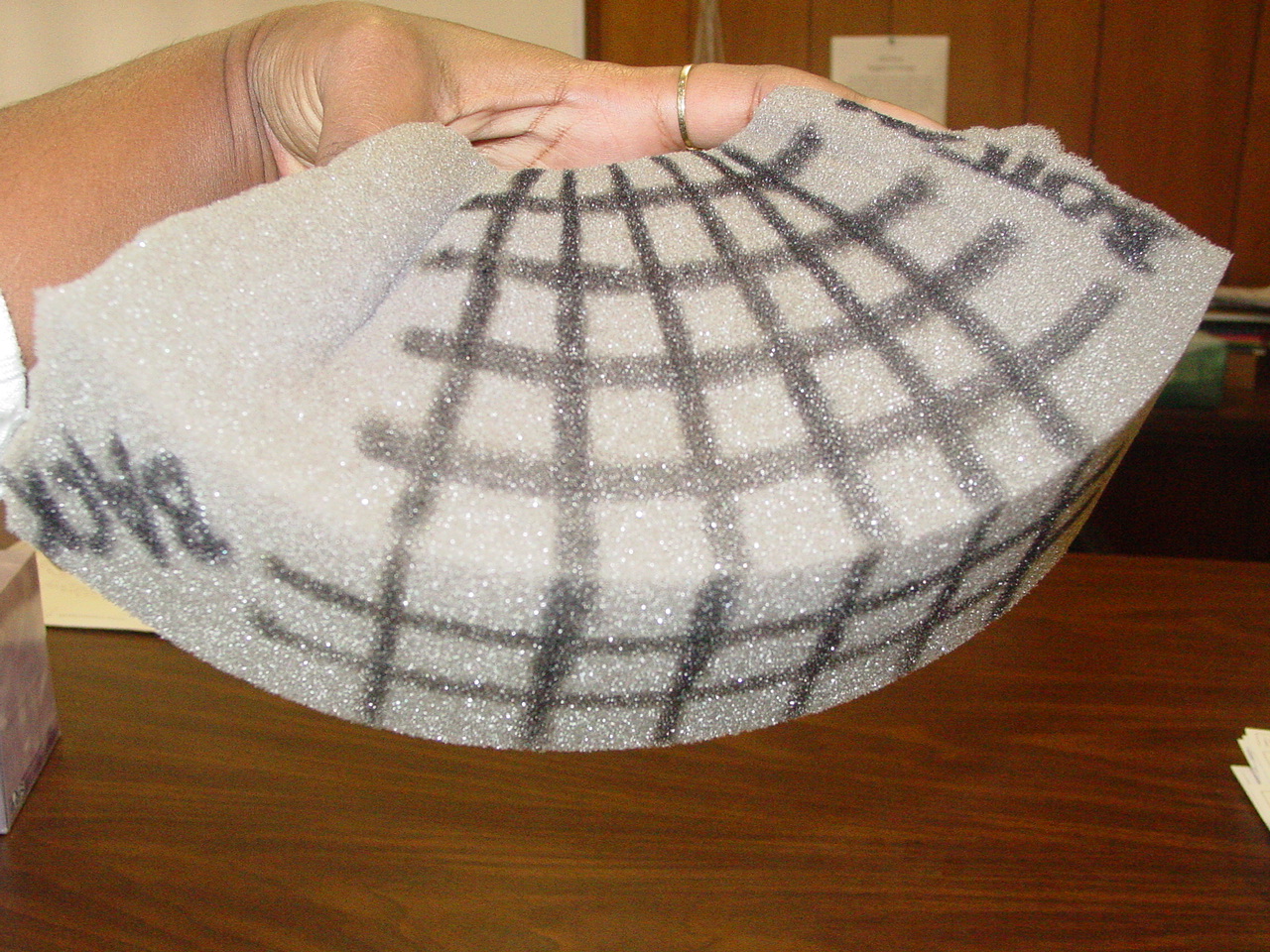

Some materials will change shape, or deform when in tension or compression, although sometimes this is difficult to see. In the pictures below, an even grid has been drawn onto a rectangular beam made of foam (in this case, packing material for a computer). The foam is then stretched by two people pulling at either end or squeezed by people pushing on the ends.

|

|

|

| stretched | |

squeezed |

As we stretch or press the piece of foam together, you may be able to see some small changes in the distance between the lines on the foam. As the lines become closer together, the foam is undergoing compression; as the lines become further apart, the foam is experiencing tension.

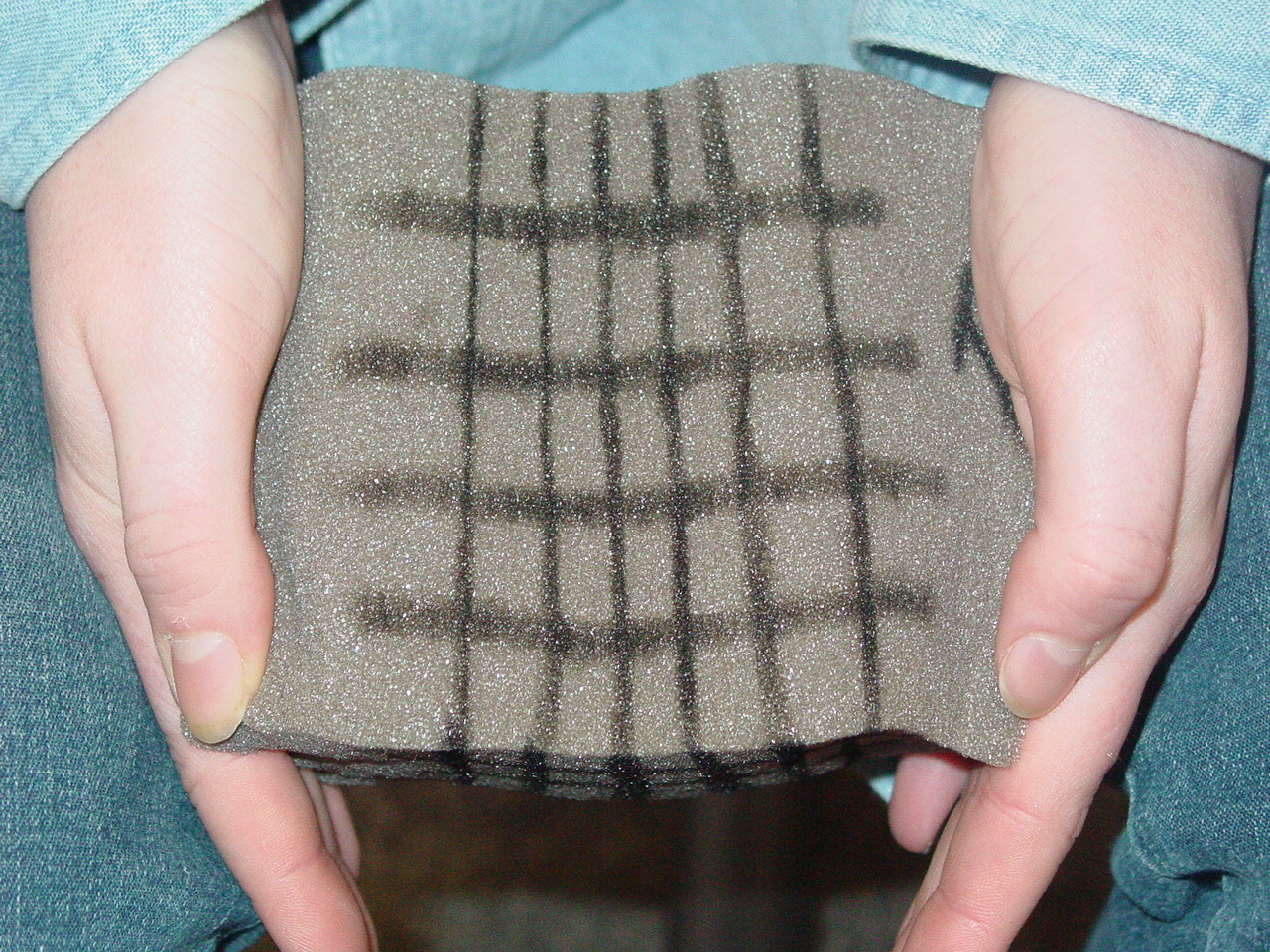

For a long, thin material, it is often easier to see both tension and compression when the material is experiencing bending. If we support the foam on both ends (by holding it or setting it on a table), and then press down in the middle of the foam piece, the foam will deform from it's original straight shape to a bent curve. What do you notice about the grid?

|

As we pressed towards the ground, the top of the beam is compressed, which is indicated by the lines on the top (or inside of the curve) becoming closer together. On the bottom of the grid (outside of the curve), the opposite happens - the lines grow further apart, indicating the tension of the bottom of the foam.

|

|

|

| The top | |

The bottom |

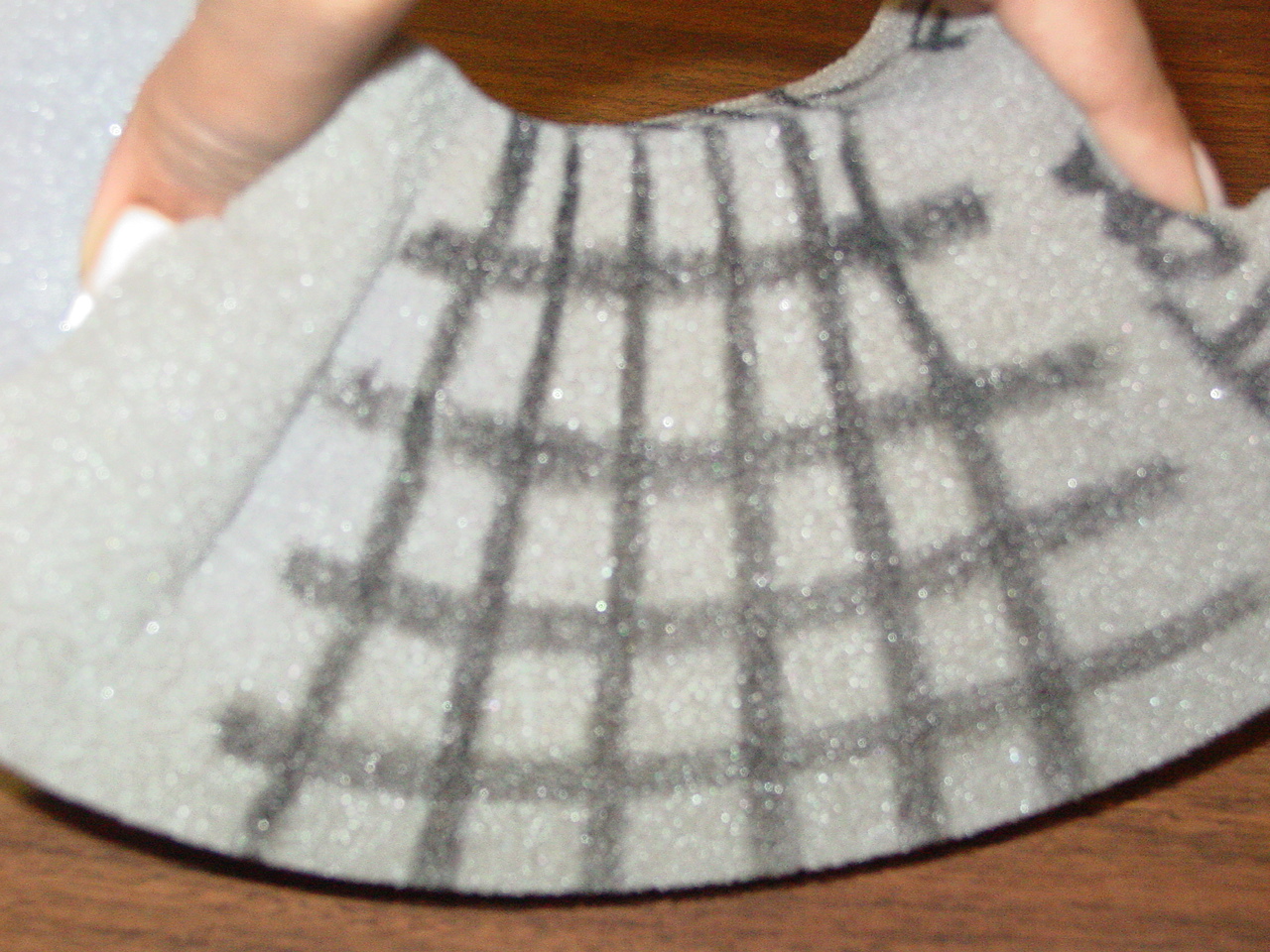

If we hold down the ends of the foam and try pressing the middle of the foam up rather than down, what happens? In this case the foam piece still experiences bending, but the tension and compression are reversed. Here, the top of the foam experiences tension, while the bottom of the foam is in compression.

As illustrated by the piece of foam, structures like bridges can also experiences tension and compression when pushed or pulled from above, below, or even from the sides of the bridge. 'Pushes' and 'pulls' are known as forces, and forces that are applied to engineering structures are called loads. Loads for real-life structures may come from things like the traffic on a bridge, strong winds, earthquakes, piled snow, and even the weight of the bridge itself due to gravity.

According to the laws of physics, "For every action there is an equal and opposite reaction". Structures are usually supported by some sort of foundation - often the 'ground' or something built into the ground. When a structure is subject to loading forces, it in turn exhibits forces on its supports, which also exert forces back on the structure (to 'hold it up'). These kinds of forces are called reactions.

Let's use a computer program to see how tension and compression occur in a virtual bridge, given certain loads and reactions.